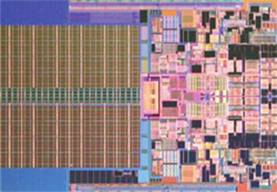

The Penryn CPU is another in Intel's line of Core 2 processors and the first fabricated using its 45nm die technology. The processors replace the 'Merom' range of processors, the and dual- and quad-core versions catering for the differing requirements of consumer machines. The Penryn is … [Read more...]

Guide to the Intel Core 2 Quad and Extreme processors

In November 2006 Intel released the first in their range of Intel Core 2 Quad processors. Codenamed the 'Kentsfield', the newly released processors were two Core 2 Duo chips connected by a 1066 MHz FSB all continued on one multi-chip module. The series number for the more powerful Core 2 … [Read more...]

Illustrated guide to high-k dielectrics and metal gate electrodes

The Penryn processor debuted Intel's 45nm fabrication, and was the first to utilize high-k gate dielectrics and metal gate electrodes. This change in technology was significant for a number of reasons: the processes used were far in advance of Intel's competition it provided a basis on which … [Read more...]