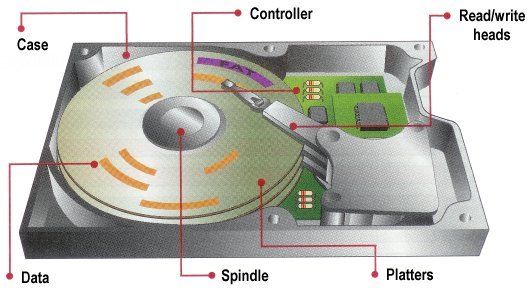

The disc platters are mounted on a single spindle that spins at a typical 10,000rpm. On EIDE and SCSI drives the disk controller is part of the drive itself. It controls the drive's servo-motors and translates the fluctuating voltages from the head into digital data for the CPU. Data is … [Read more...]